La Folie des Concours: The Desperate Preparation

Images: T.R. Raghunandan

Truth be told, nobody believed that we would drive to Vadodara for the Tenth Edition of the 21 Gun Salute Concours de Elegance, in January 2023. When the event was announced in early 2022, many Karnataka Vintage and Classic Car Club (KVCCC) members in Bangalore gave in our names for participation.

For me, Dev, my 1946 MG TC—named for the dashing Bollywood star Dev Anand—was a natural choice. For one thing, the MG Car Company was sponsoring a separate MG class and it would be nice for my car to participate with a bunch of distant cousins, I thought.

And then nothing happened, as usual. Dev waited by the wayside as other restorations and drives clamoured for attention. On 27th November, I contemplated Dev as he stood under a spreading tree at a city car show. He ran well, except for a leaking nearside rear wheel oil seal, but looked decidedly scruffy. We had a month to go and there was a lot to do.

My restorer, Sai Krishna, is as phlegmatic as his father, the late Mr. Murthy, who looked after my sole classic car over 35 years back. Krishna knew my TC well. Furthermore, he was ready to accompany me to Vadodara—it was but natural that we would drive there—and that assured me that help would always be at hand, if something went wrong.

The TC is nothing more than a full-scale Meccano set, and so Dev came apart quite easily. Though everything mechanical was more or less in its place, the cosmetics needed refurbishing.

A year back I had celebrated the lifting of the lockdown with a drive in the rain to an iron ore mining area. Sloshing through iron ore-suffused orange puddles had spoilt the paint considerably, below the wings. The paint on the bonnet, scuttle and front chassis showed signs of wear. The underneath was coated with oil-soaked mud, due to a leaky differential pinion seal.

While Krishna worked on the mechanicals, I focused on the cosmetics. My list of details that needed work, ranging from a faulty speedometer to stickers that embellish the air cleaner, came up to sixty items. Days, and some nights, were devoted to scraping away the grime and dirt earned through hard use, and spraying paint over the scratches and dents underneath.

However, as December progressed, it was clear that we were dropping behind in the race for preparation. Cosmetics take time to get right, and some things became intractable. Take for example, the speedometer.

The early TCs used the same pre-war chronometric mechanism with its jerky forward movements. While reproduction meters usually used the later electromagnetic mechanism, using them was a giveaway, as the position of the odometer and trip meters on them were reversed.

A look inside the complex clockwork of Dev’s speedo revealed that there was play everywhere. The instrument had seized at some time and that resulted in the square hole insert for the speedo cable to round off. Desperate situations call for desperate measures; so, we fitted a spare chronometric speedo we had in stock and prayed that it would work. It did not. After a rich flow of expletives, we focused on the things we needed to do next.

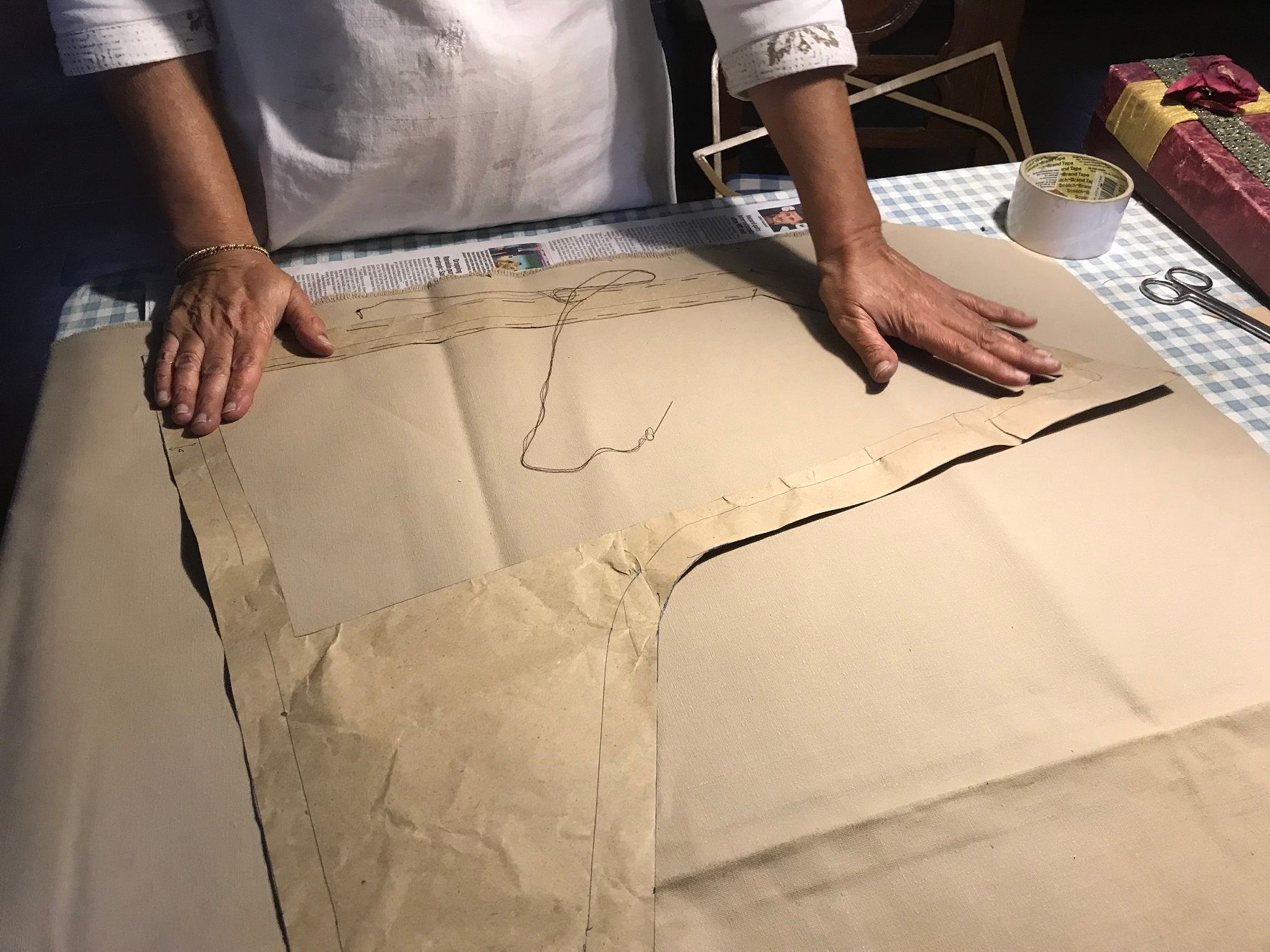

The side curtains for the TC are a pretty and important addition to the car’s cosmetics. Buying them from abroad would cost a fortune, so my wife volunteered to stitch them. I attempted to borrow an industrial sewing machine, which weighs a ton.

My wife recoiled in horror at the prospect and proceeded to use her own normal machine. Using paper patterns, she hand-stitched a mock-up of the finished screen and ran the seams on her machine. I bevelled the strips of stainless-steel beading and cut the celluloid windows, for the final fitting just hours before we were to hit the road.

The wiring loom was also imported as cloth braided wire in the right colour code is unavailable in India. However, we discovered that some things can be locally sourced. The wiring passes through a flexible metal pipe in the engine bay, where it loops underneath the chassis and goes into the front wing stays.

While these cost a king’s ransom if imported, they are nothing more than the metal casings used for health faucets in Indian toilets! It cost very little money to get the whole set up done well, but the source of our material raised a few laughs.

The other challenge was to persuade the electrician to not use modern plastic connectors, and to completely avoid using modern plastic tape for fitment of the wiring. He sighed in resignation, at my complete impracticality. I told him that the car would not win any competition if such fittings were used, but I don’t think he was convinced.

As D-Day neared, we worked with feverish haste, often late into the night. There were many unforced errors, some cosmetic work was abandoned—we just did not have the time. For example, the TC has a flexible board covered with rexine to mask the underneath of the dash and hide the tangles of wire that lie behind. We began work to cut it to shape but did not have the time to fit it.

We planned for a test drive of 200 kilometres, which never happened. A slow drive through the city traffic a day before we left Bangalore was all we could manage. Dev ran well, the brakes were a tad spongy, but would hold.

Would Dev run all the way to Vadodara? We banished such doubts from our mind and slept well the previous night.

Comments

Sign in or become a deRivaz & Ives member to join the conversation.

Just enter your email below to get a log in link.