Škoda 1100 OHC Coupe: Reviving A Legendary Sports Racing Machine

Images: Škoda Auto

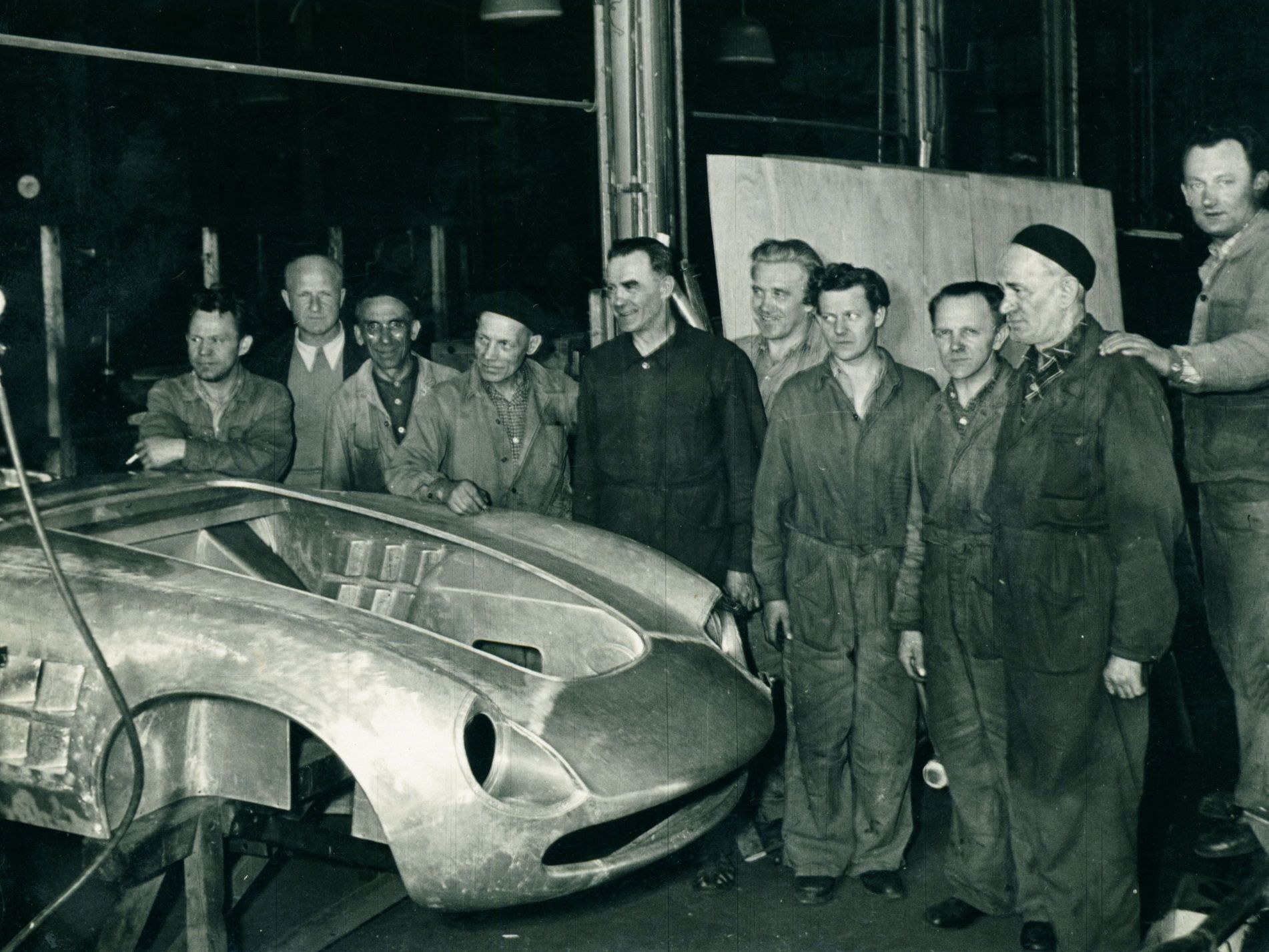

Planning for the Škoda 1100 OHC (internal type designation 968), which was intended primarily for endurance circuit races, began as early as spring 1956. By the end of 1957, the first of two copies with open GRP bodywork had been completed. This vehicle is still among the highlights of the Škoda Museum exhibition in Mladá Boleslav. It regularly competes in national and international classic car events. The second 1100 OHC is part of Škoda UK’s heritage fleet.

In 1959/1960, the designers continued working on the 968 project and created two Škoda 1100 OHC Coupes with closed bodywork. Tried-and-tested components from Škoda’s production models were used. However, unlike the Škoda Sport and Supersport, which were created at the end of the 1940s, the vehicle was no longer based on a central tube with forks for an OHV engine to be mounted at the front.

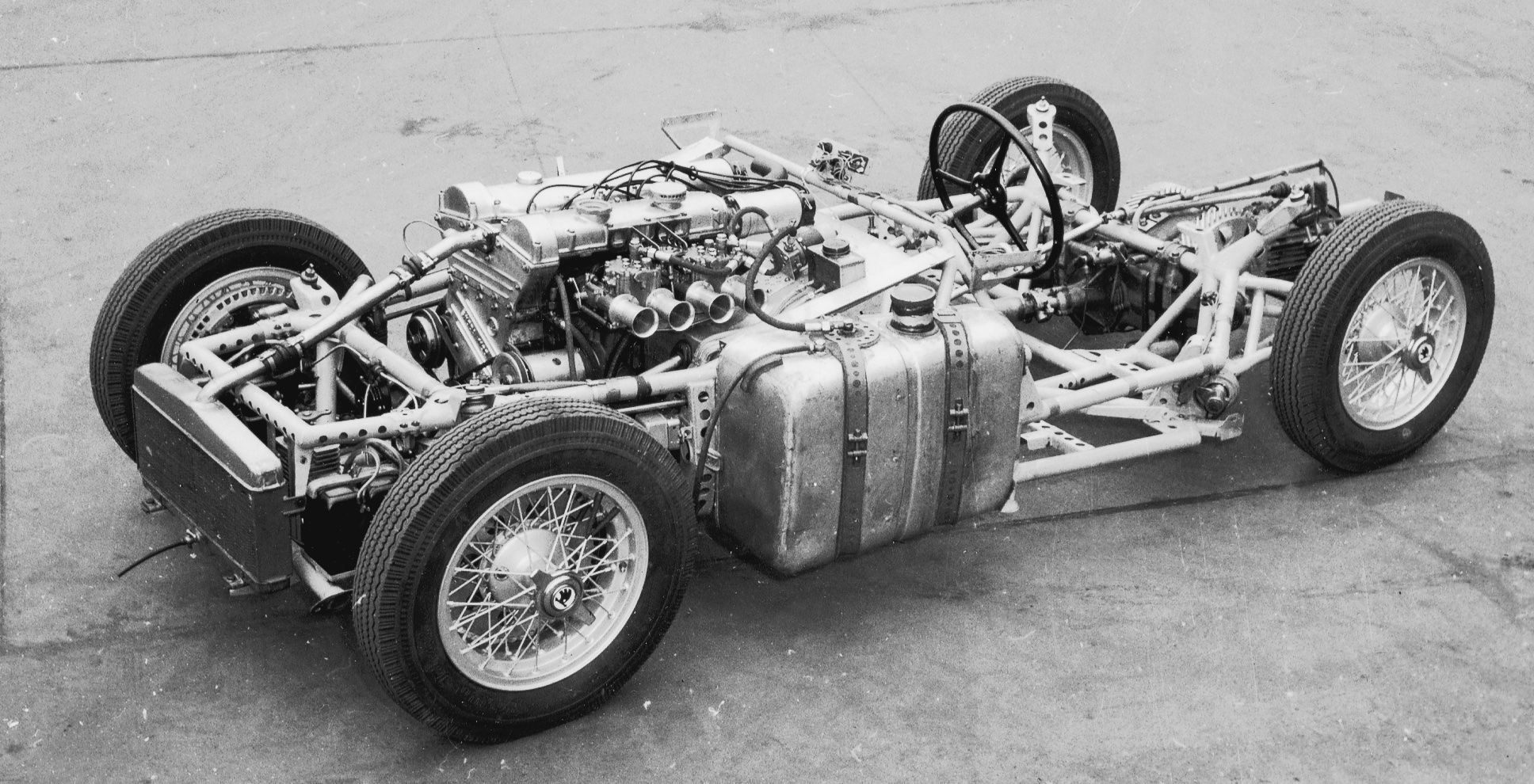

Instead, the Škoda 1100 OHC Coupe took advantage of a lightweight, yet rigid truss frame welded from thin-walled tubes. Trapezoidal suspension, consisting of two triangular wishbones arranged one above the other, was used for the front wheels, while a coupling axle with trailing arms was installed at the rear.

The engine was located behind the front axle and, along with the assembly unit, comprising rear axle differential and five-speed gearbox, achieved an almost ideal weight distribution. The handling of the dynamic racing car was outstanding.

The Škoda 1100 OHC Coupe was powered by a naturally aspirated in-line four-cylinder engine. The cylinder and crankcase were made of aluminium and were derived from the ŠKODA 440 ‘Spartak’, as was the crankshaft.

However, the racing car significantly exceeded the Spartak’s output of 40bhp, thanks to its optimised combustion chambers and OHC valve drive, a compression ratio of 9.3:1, two carburettors, double dynamo battery ignition from Bosch, Scintilla Vertex magnetos and many other modifications. Its output was 92bhp at 7700rpm, with an impressive 85bhp per litre of displacement.

For short bursts, it could reach up to 8,500 rpm. Depending on the overall gear ratio, which could be adjusted according to the specific racetrack, the two-seater with aluminium bodywork and an unladen weight of only 555 kg reached a top speed of around 200 km/h. Dual-circuit brakes always ensured effective deceleration, and to reduce the unsprung mass, rear drum brakes were mounted on the differential gear.

The racing career of the two Škoda 1100 OHC Coupes lasted from 1960 to 1962. In 1966, they were sold to private buyers when they were no longer allowed to compete due to changes in technical regulations, which resulted in the end of the under 1100cc category. Subsequently, both coupes were destroyed in road accidents.

The owner of the first vehicle, the surviving components which were used in the reconstruction, replaced the engine of the 1100 OHC with a production four-cylinder with OHV valve timing from a Felicia. The original engine was on display for a long time in the vocational school in Mladá Boleslav before it was finally installed in the reconstructed 1100 OHC Coupe.

The second coupe caught fire in an accident. The driver managed to escape from the vehicle, but the aluminium bodywork was irreparably damaged. The dismantled one-of-a-kind rear axle with integrated gearbox had been part of the collection at the National Technical Museum in Prague before it was donated to the Škoda Museum 25 years ago.

The Škoda Museum acquired the truss frame, which had been cut into three parts, along with the complete front axle and other surviving parts from a private collector in 2014.

The ambitious project to restore the vehicle would not have been possible without the experts from the Škoda Museum and their experience of working on the open Škoda 1100 OHC. The original technical documentation was also crucial to the project’s success. Almost all of it had been preserved in the Škoda Auto archive, including an explanation of each production section and an explanatory drawing for the installation of individual assemblies.

The original mechanical components had very little wear, as the car had only participated in a few races. The renovation of the entire chassis, along with a newly reconstructed radiator, fuel tank and other elements, was completed at the end of 2015.

Comments

Sign in or become a deRivaz & Ives member to join the conversation.

Just enter your email below to get a log in link.